INSTALLATION INSTRUCTIONS

The installation of the chimney fan is estimated to take an

average of 15 minutes, when installed on a brick chimney or a steel chimney. The

installation time does not include: setting up ladder, lifting fan to the top of

the chimney, cutting back flue tile etc. Only the installation of fiber mat,

mounting brackets, steel chimney adaptor, safety wire, and junction box is

included. Open the carton and remove all packing materials. The standard chimney

fan package includes: chimney fan w. bird screen, 3-4 ft cable in conduit,

weatherproof junction box (not shown), fiber mat, safety wire with anchor,

Installation brackets (set of 4), motor speed control (not shown), Installation

Instructions and a Warranty Registration Card.

Make sure the axial vane turns without making noise or offering

resistance. Also make sure it is in balance.

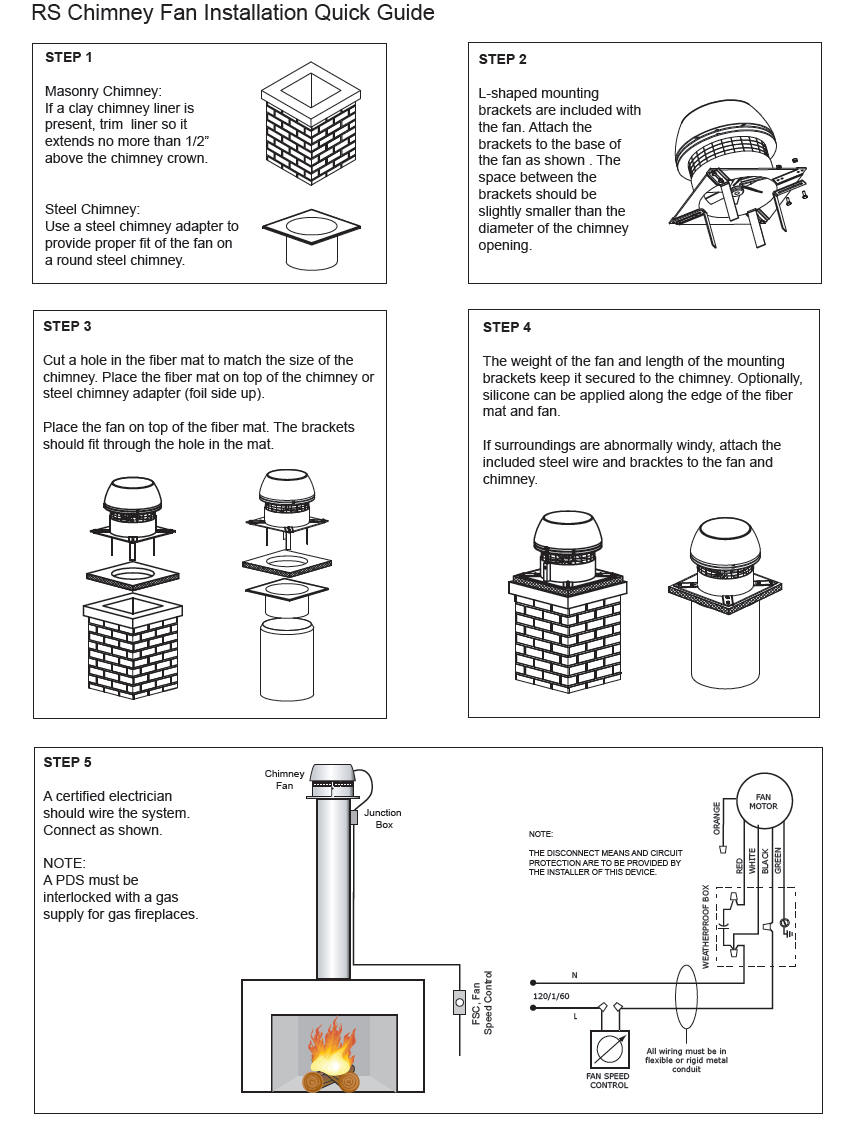

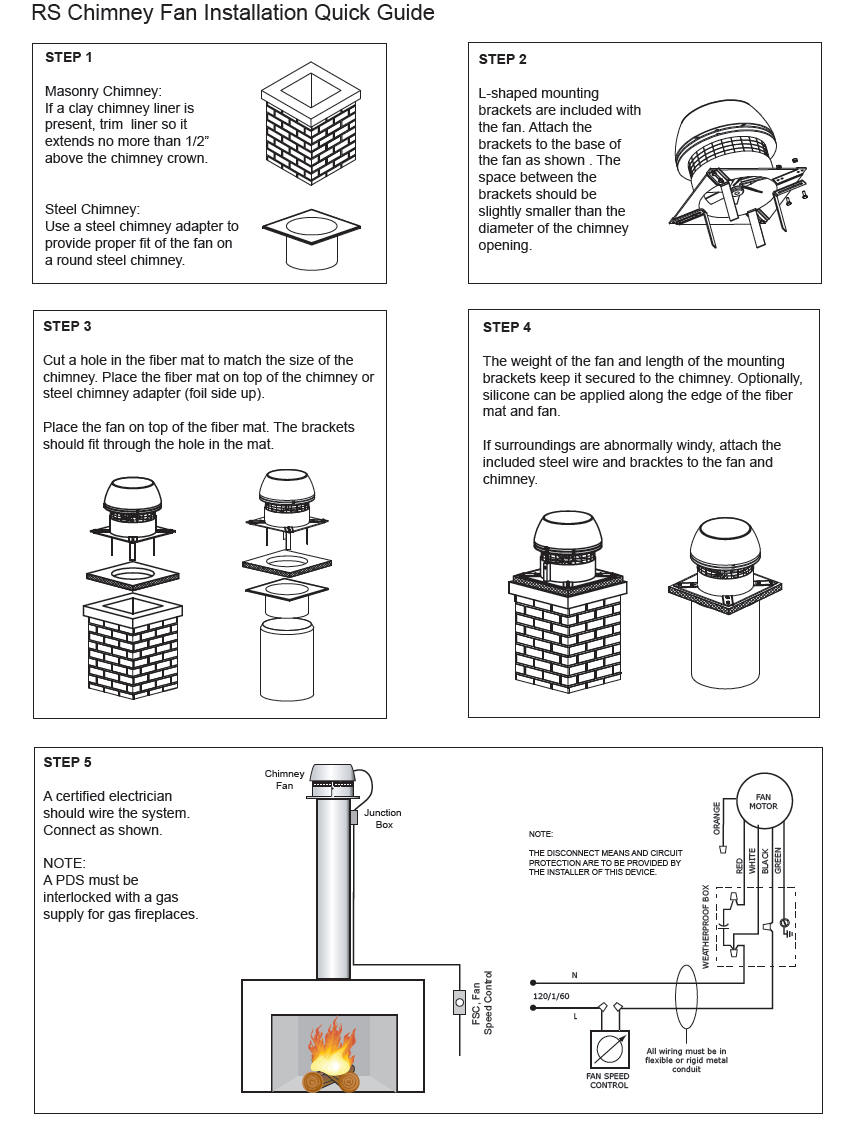

Installation on brick chimney.

The installation procedure is the same whether the flue is round

or rectangular. If a clay tile flue liner is installed, it might stick up a few

inches. Cut it back so it is flush with the chimney crown.

Step1:

Prepare fan location

The installation procedure is the same whether the flue is round

or square. If a clay tile flue liner is installed, it might stick up a few

inches. Cut it back so it is flush with the chimney crown.

Measure the inside diameter of the flue, cut a corresponding

hole in the fiber mat leaving a minimum distance of 3/4" to any side of the

fiber mat.

The aluminum foil on the fiber mat must face upwards (against

fan base).

Step 2:

|

|

Preparation of fan

Locate the installation brackets in the grooves on the underside

of the fan base using the bolts and nuts supplied, to secure the brackets. Note

that the bolts shall be installed from the bottom side in the two inner holes.

Adjust the final position of the installation brackets ensuring

that there is clearance between the brackets and the flue wall. If the brackets

touch the flue wall, it is likely to create some noise from the vibration.

|

Step 3:

The chimney fan is now ready for installation on the top of the

chimney. Place the fiber mat on the top of the chimney, with the aluminum facing

upwards, and place the fan on the top of the mat.

Step 4:

Decide on the location of the bolt and wall plug (1). Drill a

hole in the stack and secure the safety wire by the bolt and the wall plug. Take

the safety wire through the hole in the fan base and return it to the free clamp

of the wire. Tighten the safety wire slightly (2) and crimp the free clamp to

provide secure anchoring for subsequent safe cleaning and service. Fit the

liquid tight junction box (3) on the outside wall of the chimney stack, but make

sure the conduit is 10-12" away from the fan outlet. Run the installation cable

to the fan speed control/switch and the main electric supply.

Caution:

Under conditions with extremely strong winds constantly surrounding the top of

the chimney, the chimney fan must be secured by steel wires or similar.

Chimney Fan Wiring

Special Applications.

1. High temperature applications.

If the fan is used for applications where the flue gas

temperature exceeds 400°F at the exit point, but does not exceed 650°F, dilution

bolts must be used. Typical situations are chimneys that are only 6-8' high.

Dilution bolts will cause cool air to mix with the warm exhaust gas as they will

lift the fan from the chimney and leave space so the cool air can get in.

The dilution bolts should be installed in the outer holes in the

fan base. The dilution bolts should be adjusted in height, so the flue gas

temperature does not exceed 400°F when discharged through the fan. However, in

order to minimize soot deposits make sure the temperatures is above 320°F. When

using dilution bolts the fan’s actual capacity decreases and you might need a

stronger model. Fiber mat is not required when using dilution bolts.

2. The Flue is Bigger than the Fan Base.

|

If the flue size exceeds the size of the fan base, it is

necessary to alter the top of the chimney by installing a support flange, made

out of stainless steel, as shown.

The support flange must be secured and the hole in the center

must be 12" in diameter.

Note: Using only one flue

can cause problems with flow noise due to high velocities. Chimney fans

operating in tandem should always be of the same size.

|

|

3. The Flue Pipe is Higher than the Chimney.

In many cases, the chimney is designed so the liner or the

chimney insert sticks several inches up over the chimney top. If it is a few

inches, it’s recommended to install the chimney fan on the top, provided the

pipe will give enough support for the fan. If there’s insufficient support, the

liner or the flue must be cut back, so it is flush with the top of the chimney

and the chimney fan can be installed as described in the previous.

4. Two Flues Servicing One Fireplace

This solution is used by many designers when the fireplace

opening is large, and the total flue opening must be larger than a standard pipe

or liner. By installing two separate flues the builder has accomplished a total

flue opening big enough for the fireplace opening. When sizing a chimney fan for

this kind of application, there are two ways to go about it: One of the flues

must be shut off or disconnected and the chimney fan installed on the open flue,

or A chimney fan should be installed on each flue and operate in tandem.

Exhausto Fans...the

ultimate draft solution.

|